The basic configuration of traditional propellers has not fundamentally changed since the first powered flight by the Wright brothers in 1903.

However, as engineers learn more about aerodynamics and attempt new experiments, propellers are evolving to more complex shapes. These feature multiple blades, high sweep angles, blade tip devices and other features to optimise performance in different conditions.

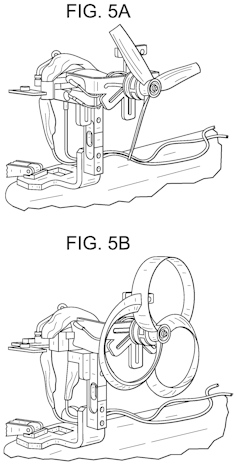

A recent advancement in propeller technology are “toroidal” propellers. These devices are ring-shaped, with the blades looping around each other. A few recent articles and videos have been hyping these – but how “revolutionary” are they, really?

Refining the shape

In 2017, researchers at MIT filed a patent for toroidal propellers. Their patent claims the invention is more efficient than traditional propellers and is less noisy.

Coincidentally, already in 2012, US engineering company Sharrow Marine also developed a toroidal propeller for boats; they have demonstrated it to be more efficient and quieter than traditional marine propellers.

The reason toroidal propellers may be quieter is because of their complex shape – it minimises the strength of the vortex (a spiralling movement of air, water, or another fluid) that naturally happens over propeller blade tips.

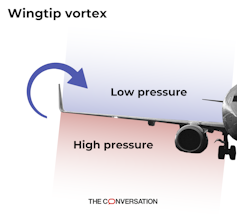

This happens because there’s a high-pressure region under the blade, and low pressure above it. As high-pressure air from under the blade moves towards the low-pressure region above it, it travels in a spiral – a vortex.

This phenomenon is not unique to propeller blades, which are essentially rotating wings. The wing of a plane also experiences this phenomenon. Engineers have done much research on wingtip devices that can minimise this.

The use of closed-loop structures – like in a toroidal propeller – is one way of reducing tip vortices.

Even though the basic propeller shape has remained the same since its invention, many propeller blade designs have been put forward. To test these, engineers need to perform design trade-off studies. Some of these approaches have been tested to try and make helicopter blades and drones more efficient and less noisy.

No magic propeller

It’s important to understand propeller geometry must be optimised for a specific “operational envelope”. This means the properties of the fluid or air it operates in, rotation speed, forward speed, and other details. Outside that envelope, the propeller will perform poorly.

So far, nobody has achieved the magical propeller geometry that will achieve low noise and high efficiency for all operating conditions and scales. Toroidal propellers are no exception – from the sparse results available so far, their advantages are not yet fully quantified.

Comparing a well-designed toroidal propeller to a poorly designed traditional propeller will show a significant improvement, but is not a fair comparison.

Well-designed toroidal propellers may have advantages in specific operating conditions, such as dense fluids or a specific range of speeds. However, the question remains as to how a toroidal propeller compares to a well-designed traditional propeller for the same conditions.

This is a challenge, since improvements are always relative to a benchmark – which may not be the most efficient design to start with.

Another aspect of a fair comparison that doesn’t seem to have been published for toroidal propellers is comparing different propellers at the same thrust force. Only then you can see the true advantages regarding noise reduction and energy required to spin the propeller.

Home experiments are not representative

An MIT announcement earlier this year about toroidal propellers winning one of MIT Lincoln Laboratory’s 2022 R&D 100 Awards generated significant excitement. There’s been widespread experimentation with 3D-printed toroidal propellers, but not all of these have delivered positive results.

This may be due to un-optimised geometry and poor scientific rigour by the general public conducting some of these experiments. This gives the scientific community a research opportunity – to truly assess and optimise toroidal and traditional propellers to enhance their performance.

Previous optimisation studies have been conducted, some of which even use machine-learning techniques to identify suitable geometries. Engineers are also trying to make propellers that sound less annoying, by considering how humans perceive sound.

Expensive and hard to scale

Toroidal propellers also have clear disadvantages. The main one is the difficulty to scale them to mass production due to their complex geometry, which leads to high production costs.

The complex structure also requires special care to avoid unwanted vibrations – a significant issue when rotating at high speeds. This also adds to higher manufacturing costs.

When it comes to using toroidal propellers for drones, their heavier weight will also have implications on the responsiveness and stability of the drone. This is critical when operating in windy and turbulent conditions such as windy weather.

Overall, toroidal propellers are an exciting recent development in propeller design, at least in some cases. While they can be more quiet, they won’t completely replace traditional props just yet – there’s no single propeller design that will suit all situations.

Abdulghani Mohamed, Senior Lecturer in Aerospace Engineering, RMIT University

This article is republished from The Conversation under a Creative Commons license. Read the original article.