In our everyday life, we are surrounded by objects that have properties enabling them to perform certain functions. Rigidity and softness enable an object to perform a specific function. These propoerties are seemingly opposing in nature, and one property cannot be traded for another.

For example, pillows are soft to provide the necessary cushioning and comfort. A rolling pin is rigid and round to be able to roll over dough. Once these objects are fabricated, those properties cannot be changed. A pillow cannot flatten dough, and a rolling pin cannot provide support for a head and neck.

But imagine if an object as soft as a pillow could transform into an object as stiff as a rolling pin. With a simple switch, that object could acquire the properties and functions of a stiff material and, with another click, those of a soft material.

A material that could do this would allow an object to have multiple functions. This multifunctionality would inherently bring a substantial drop in the use of our resources. It would represent a paradigm shift for the sustainable future of everyday technologies.

Future materials

Along with other material scientists, physicists and engineers, my research investigates what we describe as reconfigurable mechanical metamaterials. These are a class of re-programmable multipurpose metamaterials with a transformable internal architecture.

These materials have three antagonist — seemingly counteractive — properties: floppiness, rigidity and multistability. This means that a user can re-program, on demand, their properties to be either stiff or soft or, if needed, even multistable.

An object made by this all-in-one class of metamaterials can become rigid to resist the application of external forces as a stiff structure, shape morph as a floppy mechanism, or trap and absorb energy as a multistable material.

After fabrication

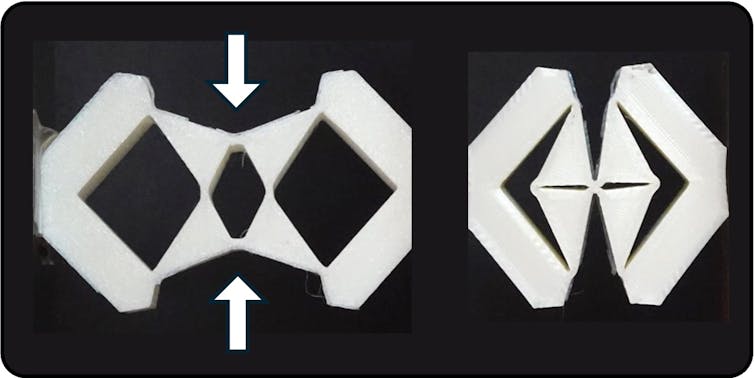

A material that can acquire — post-fabrication — the traits of either a structure, a mechanism or a multistable matter does so because of the arrangements of its building block, in this case, a meta-hinge.

This rearrangement can be triggered through the application of forces at particular pressure points. During the reconfiguration process, their edges come into contact, eventually merge, and close the central void, forming a flexible hinge. In one configuration, the building block is rigid because the metal hinge is not formed, whereas, in the other, the activation of the meta-hinge generates local rotation around the central pivot, making it floppy.

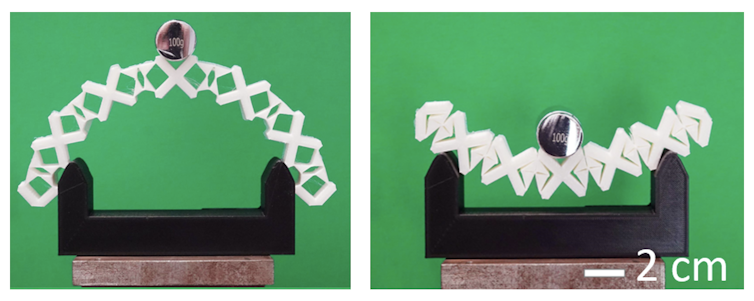

The reconfigurable building block can be used to create multifunctional structures with re-programmable properties. For example, a one-dimensional beam can be made to behave as either a stiff or floppy structure under a load applied at its midspan.

On the other hand, tessellating the building block in two dimensions allows the creation of three types of reconfigurations, each corresponding to a given class of macroscopic solids, either rigid, floppy or multistable at the verge between the two. Extensions to three dimensions are also possible.

Applications of metamaterials

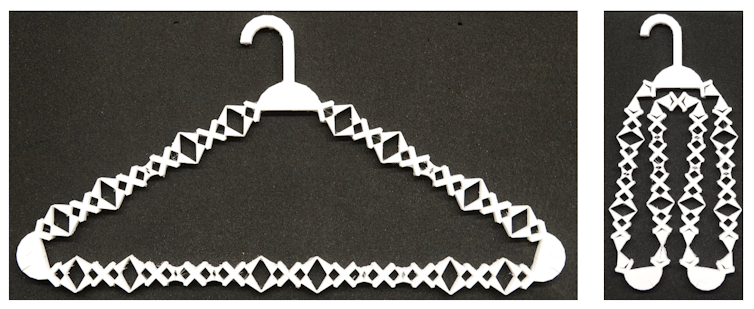

Multifunctional products that can benefit from property reprogrammability span multiple sectors. In addition to physical properties, other geometric properties can be re-programmed. For example, the reconfigurability of the unit cells can bring overall changes in the size and shape of a product.

A multifunctional coat hanger is just one example. By selectively activating certain hinges, the coat hanger can collapse for space-saving and ease of transportation, as well as be deployed when needed in different sizes and forms to accommodate clothing of different sizes. This provides an unprecedented level of multifunctionality, leading to sustainable resource use.

This all-in-one class of metamaterials helps create multipurpose products. This multifunctionality promises to reduce the use of resources, open a sustainable pathway to our future technology and contribute to attaining the sustainability targets our world has set, thereby paving the way for a greener and more resilient future.

Damiano Pasini, Professor of Mechanics and Materials, McGill University

This article is republished from The Conversation under a Creative Commons license. Read the original article.